India’s biofuel policies have experienced a major transformation in 2025, driven by ambitious government targets, cutting-edge technology from companies like Khaitan Bio Energy, and a strong push to blend biofuels with conventional fuels. These developments are changing India’s energy landscape and helping the country move toward a sustainable, low-carbon future.

Rapid Growth in India’s Biofuel Sector

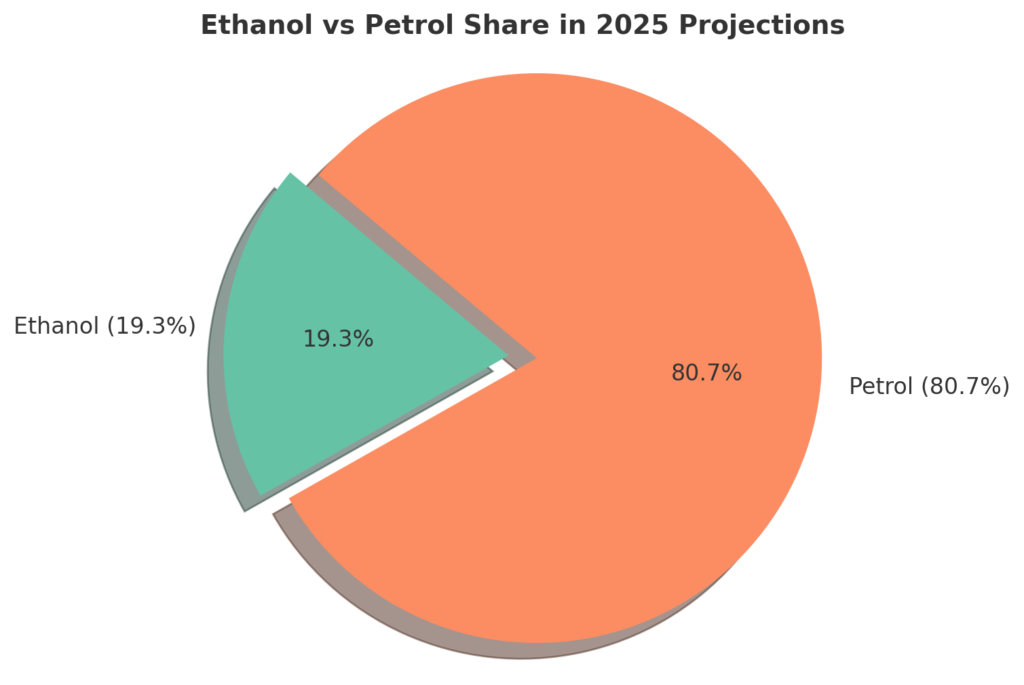

India has achieved a milestone by reaching 20% ethanol blending in petrol five years ahead of schedule—a feat celebrated by both policymakers and environmentalists. This target, previously set for 2030, was brought forward to 2025-26 under the National Policy on Biofuels (2018, amended in 2022). The policy prioritizes a diverse mix of biofuel sources such as sugarcane, maize, damaged food grains, and agricultural residues, aiming to stabilize supply while minimizing risks to food security.

Ethanol Blending: India’s Flagship Achievement

- In July 2025, the ethanol blending rate reached 19.93%, just shy of the official 20% goal.

- Ethanol blending has reduced oil imports, saved billions of rupees, and cut millions of tonnes in carbon emissions since 2014.

- India now requires an estimated 10 billion liters of ethanol annually to sustain E20 blending, prompting relaxation of restrictions on ethanol production from sugarcane derivatives.

Expanding the Biofuel Push Beyond Petrol

Notably, India is preparing to extend biofuel blending to the diesel-powered construction and heavy industry sector. Discussions between key ministries aim to mix biofuels into diesel for commercial equipment, marking a significant expansion from current petrol-centric programs. With diesel consumption far exceeding petrol, this initiative has the potential to further accelerate India’s green energy goals.

Government Policies and Support Mechanisms–India’s Biofuel Policies

Enabling Environment for Ethanol Production

Several policy changes have catalyzed biofuel growth:

- Ethanol procurement prices are now governed by an administered mechanism, improving financial incentives for producers.

- GST for ethanol used in blending has been slashed from 18% to 5%, lowering overall production costs.

- The government has lifted all major restrictions on ethanol production from sugarcane juice, syrup, and molasses for the 2025/26 supply year, allowing sugar mills and distilleries to scale up output without caps.

- Robust financial schemes like the Ethanol Interest Subvention Scheme (EISS) and Long-Term Offtake Agreements (LTOAs) ensure stable demand and timely payments under the Ethanol Blended Petrol Programme.

- Dedicated support for cooperative sugar mills and multi-feedstock distilleries has enabled diversification in ethanol feedstock, promoting production from agricultural waste and non-food crops.

Supporting Advanced Biofuel Technologies

The “Pradhan Mantri JI-VAN Yojana” encourages setting up projects that use agricultural and forestry residues, industrial waste, and algae to make advanced biofuels. Financial assistance is provided for these plants as part of the government’s strategy to advance second-generation (2G) and even third-generation biofuels.

Recent Challenges and Ongoing Debates Regarding India’s Biofuel Policies

Impact on Farmers and Food Security

While the biofuel revolution brings energy independence, it is not without challenges. Increased demand for maize (corn) and other feedstocks is affecting small poultry farmers by driving up the price of livestock feed. Therefore there are ongoing debates on balancing the use of food crops for fuel against the country’s food security needs.

Technological and Infrastructure Issues

Many current vehicles are not compatible with the new E20 fuels, raising concerns among consumers about engine performance and longevity. So many ongoing research is working to address these compatibility issues and educate the public on the benefits and risks of biofuels.

Khaitan Bio Energy: Leading the Transformation

Pioneers of Second-Generation Biofuels

Khaitan Bio Energy is at the forefront of innovative biofuel technology in India. The company’s patented technology produces second-generation (2G) ethanol from cellulosic materials like rice straw—an agricultural waste commonly burned in fields, causing massive air pollution. Thus their breakthrough process utilizes all components of lignocellulosic biomass, resulting in high-value bioenergy products and substantially reducing stubble burning.

- The company set up a pilot plant for rice straw management in partnership with BIRAC in 2021, validating its approach and revealing its commercial potential.

- Khaitan Bio Energy’s patented technology has been certified at Technology Readiness Level – 8 (TRL-8). This is by the Department of Biotechnology. Government of India and has also been evaluated by the Centre for High Technology, Ministry of Petroleum and Natural Gas, Government of India.

- With a focus on decarbonizing India’s transport sector, Khaitan Bio Energy’s solutions complement national efforts for a sustainable energy transition.

Sustainable Value Creation

Combining technology and sustainability, Khaitan Bio Energy embodies India’s push for green innovation. So their expertise in producing 2G ethanol and bioenergy from rice straw and other residues offers a scalable model for other regions. This approach not only tackles pollution but also creates new economic opportunities for rural communities.

Shaping the Next Decade

Khaitan Bio Energy reflects broader trends in India’s biofuel space. This is by increasing adoption of newer technologies, government backing for advanced biofuel production, and integration of waste-to-energy solutions. Therefore experts predict this synergy between technological advancements and robust policy will define India’s energy future over the next decade.

India on the Global Stage

India’s proactive biofuel policies have put the nation at the forefront of the Global Biofuels Alliance. Thus strengthening international cooperation in renewable energy and clean technology. Also events like Green Rev 2025 have highlighted India’s innovations in ethanol and compressed biogas. This is done with partnerships forming between public and private sectors to scale up green energy solutions.

What’s Next for India’s Biofuel Policy?

- Continued expansion of ethanol and biodiesel blending to sectors like aviation and diesel-heavy industries.

- Increasing support for advanced biofuel technologies to tap new feedstocks and waste streams.

- Ongoing adjustments to policy and production standards to address food security, pricing, and infrastructural compatibility.

- Steady rise in private sector innovation, with companies such as Khaitan Bio Energy shows how sustainable business can drive national change.

India’s biofuel journey in 2025 is marked by aggressive targets, sophisticated technology, and growing environmental consciousness. Thus overlapping efforts of government, industry innovators, and farmers signal that India is making rapid, meaningful progress toward sustainable energy. With Khaitan Bio Energy serving as a model for how local companies can power national transformation.