Fuel for the future generation and for sustainable environment

Second-generation Bioethanol (2G), also referred to as next-generation biofuels, are fuels that are manufactured from various types of non-food biomass. It is produced from lignocellulosic biomass, such as agricultural residues comprising stocks and stems from cereal crops like rice, maize, etc. and uses industrial by-products such as crude glycerol as feedstock. Lignocellulose is considered a renewable and inexpensive carbon source, and its availability depends on crops grown in specific regions. Various types of plant biomass, like dedicated energy crops, have also been used in the production of such biofuels. Maximum potential sources of lignocellulosic biomass include agricultural waste (wheat straw, corn cob, rice husk, cereal straw, and bagasse), industrial waste (brewer’s spent grains and grains from distilleries), municipal solid wastes (food waste, craft paper, and paper sludge containing cellulose). Forest-based woody wastes are the other potential sources of lignocellulosic biomass.

The most striking difference between first-generation and second-generation biofuels is that the former is produced directly from edible portion of crops like rice and other cereals, maize, sugar beet and cane whereas the latter is produced from industrial and household wastes and residuals.

Why is 2nd Generation bioethanol (2G) a better choice?

Bioethanol is considered to be a very effective alternative compared to fossil fuels since it is a renewable energy source which has a significant role in reducing greenhouse gas emissions. But the use of first-generation bioethanol can lead to competition between land use for agricultural purposes and energy production needs and the significant prioritization of fuel versus food. Hence, the 2G bioethanol will be an attractive option as it eliminates this issue and also allows the use of waste as biomass.

Second-generation biofuels are mainly used to overcome the constraints of original biofuels.

- The primary benefit of 2nd generation bioethanol is that it offers greater benefits in terms of environmental performance, improved energy efficiency, enhanced the ability to use lower cost and more widely available feedstock and also the ability to easily get integrated into existing fuel supply and distribution systems.

- It is a more environmentally friendly renewable fuel which can be directly used by the transportation sector as liquid fuel or by blending with petrol in specific proportions.

- Moreover, compared to first-generation biofuels, second-generation (2G) biofuels generate a higher energy yield per acre.

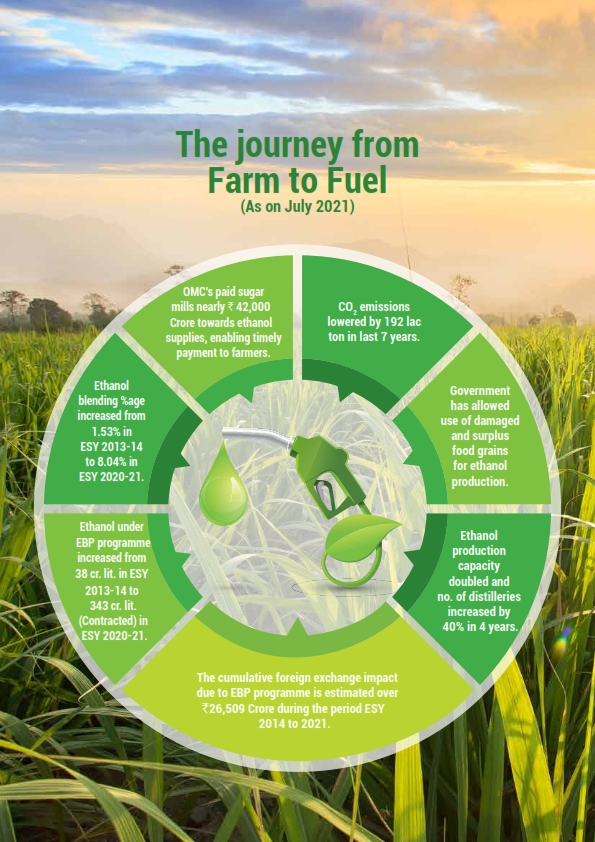

- Further, our country has been encouraging the manufacturing of 2G bioethanol to achieve its E20 target, i.e. the 20% ethanol blending in petrol by 2025. It helps the country with agricultural waste incineration and also to meet the goal of converting waste into energy.

- Converting agricultural waste into biofuels will reduce toxic air pollution to a great extent, especially in the northern states of the country, where open field burning of agricultural residues, especially during October/ November every year is a common practice.

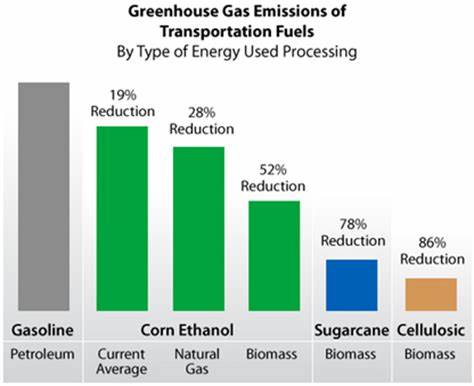

- It should also be noted that the use of biofuels to replace fossil fuels will lead to a significant reduction in GHG emissions. Studies show that 2G bioethanol has a higher GHG reduction potential than its first-generation counterpart.

- 2G biofuels are highly inexpensive compared to other existing fossil fuels.

Bioenergy Basics

To meet our growing energy demand, bioenergy will be one among many diverse resources available at the time. From burning wood to create heat to using biodiesel and ethanol for vehicles and using methane gas and wood to generate electricity can be included as examples of bioenergy. Further, it can also include the more recent forms of bioenergy use materials named ‘biomass’ such as sugarcane, grasses, straw, soybeans and corn.

In short, bioenergy is an energy source which is derived from biological sources i.e. living things and their metabolic products. It can be in the form of heat, light, electricity or fuel aiding transportation.

What are sources of bioenergy present out there?

The biological source used to create bioenergy is called biomass. At present, there are many different types which are constantly in development. And broad categories of such sources include;

- Wood including wood chips, sawdust and other forestry by-products

- Animal fat waste cooking oil

- Algae purpose-grown plants (energy crops)

- Effluents from livestock

- Human waste organic fraction of municipal waste

Thus bioenergy is diverse since the productions can be tailor-made according to different regions of the country.

Bioenergy Technologies

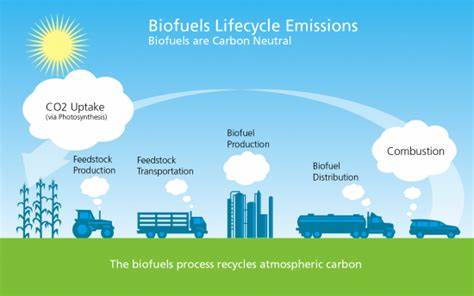

- Biofuels include fuels mainly used for transportation like ethanol and biodiesel, which are produced by converting biomass into liquid fuels. Biofuels can be used even in airlines and most vehicles on the road today. Such renewable transportation fuels, which are functionally equivalent to petroleum, will lower the carbon intensity of vehicles and airlines.

Bio-power:

These technologies convert renewable biomass fuels into heat and electricity. By the process of burning, bacterial decay, or the conversion of gas or liquid fuel. Bio-power can offset the need for burned carbon fuels, especially in power plants, lowering the carbon intensity of electricity generation. Bio-power can increase the flexibility of electricity generation and improve the reliability of electric grids.

Bioproducts:

Apart from electricity and fuels, biomass can also be converted into chemicals. It involves the production of plastics, lubricants, industrial chemicals, and other products typically made from petroleum or natural gas. The existing petroleum refinery models integrated with bio-refineries can produce bioproducts alongside biofuels. And such a co-production strategy leads to a more efficient, cost-effective, and integrated approach to the country’s biomass resources. Further, the revenue generated from such bio-products will offer added value. It also helps improve the economies of bio-refinery operations and creates a more cost-competitive biofuel.

Applications and efficiency of biomass

The application of bioenergy or biomass can be segmented into two;

- Direct Biomass Application: Direct application of biomass includes direct combustion or co-firing with fossil fuels.

- Indirect Biomass Application: There is a number of non-combustion methods available for converting biomass into energy forms. In such a process, raw biomass is converted into a variety of gaseous, liquid or solid fuels, which are directly used for energy generation. The carbohydrates in biomass, comprised of oxygen-carbon and hydrogen, can be breakdown into a variety of chemicals. And some of these can be used as fuels;

Thermo-chemical:

When plant matter is heated instead of burning, it results in various gases, liquids, and solids. And these products can be further processed and refined into many useful fuels, like methane and alcohol. Biomass gasifiers can capture methane released from plants and burn it in a gas turbine to produce electricity. Another approach to do this can be to take these fuels and run them through fuel cells, thereby converting hydrogen-rich fuels into electricity and water with few or no emissions.

Biochemical:

Bacteria, yeasts and enzymes will also turn into carbohydrates. Further, fermentation converts biomass liquids into alcohol, a combustible fuel. An almost similar process is used for converting corn into grain alcohol or ethanol, which is further mixed with the gasoline to make gasohol. Similarly, methane and carbon dioxide are also produced when the bacteria break down the biomass, which can be captured in sewage treatment plants and landfills and burnt for heat and power.

Chemical:

Soybean and canola oil, two types of biomass oils, can be used to convert into liquid fuel that is similar to diesel fuel and also into gasoline additives. Biodiesel can also be produced from algae as a source of oils. Biodiesel is produced by combining alcohol with vegetable oil, animal fat or recycled cooking grease, that can be used as an additive for minimising vehicular emissions or as an alternative fuel for diesel engines.

Advantages of a robust bioenergy industry

Studies show that abundant and renewable bioenergy can lead to a more secure, sustainable and economically sound time ahead. And this becomes possible by;

- Supplying domestic and clean energy sources

- Reducing the country’s dependence on foreign oil

- Generating more employment opportunities within the country

- Revitalising rural economies.

Grandview research on ethanol sources for production