Introduction

Every winter, the same story repeats itself in North India. The air turns toxic, visibility drops, hospitals fill up, and Delhi-NCR tops global pollution charts. While many factors contribute to this crisis, stubble burning remains one of the most visible and damaging causes.

Despite regulations, fines, and emergency measures, the problem refuses to go away. Recently, even the Supreme Court strongly criticised the Commission for Air Quality Management (CAQM) for failing to clearly identify root causes and create long-term solutions for Delhi’s worsening air quality. This highlights an uncomfortable truth: temporary bans and short-term firefighting are not enough.

What India needs is a permanent, scalable solution—one that helps farmers, reduces pollution, and supports clean energy goals. This is where 2G ethanol and Khaitan Bio Energy come into the picture.

Why Stubble Burning Continues Despite the Ban

After harvesting paddy, farmers are left with large amounts of crop residue. Clearing this stubble manually or mechanically costs time and money—two things small farmers cannot afford.

Burning fields becomes the fastest option.

Each year, millions of tonnes of rice straw are set on fire across Punjab, Haryana, and western Uttar Pradesh. The smoke travels hundreds of kilometres and combines with vehicle emissions, industrial pollution, and dust, pushing AQI levels into the “severe” category.

Key reasons stubble burning continues:

- Short gap between paddy harvesting and wheat sowing

- High cost of residue management machines

- Lack of economically viable alternatives

- No assured income from crop waste

Unless farmers see value in crop residue, the practice of burning fields will continue.

The Hidden Cost of Burning Crop Waste

Burning fields is not just an environmental issue—it is a public health emergency.

- Fine particulate matter (PM2.5) enters the lungs and bloodstream

- Children, elderly people, and those with asthma suffer the most

- Studies link pollution spikes to increased heart attacks and premature deaths

- Schools shut down and outdoor work becomes unsafe

Ironically, what is being burned is not waste—it is a valuable raw material.

2G Ethanol: Turning Pollution into Opportunity

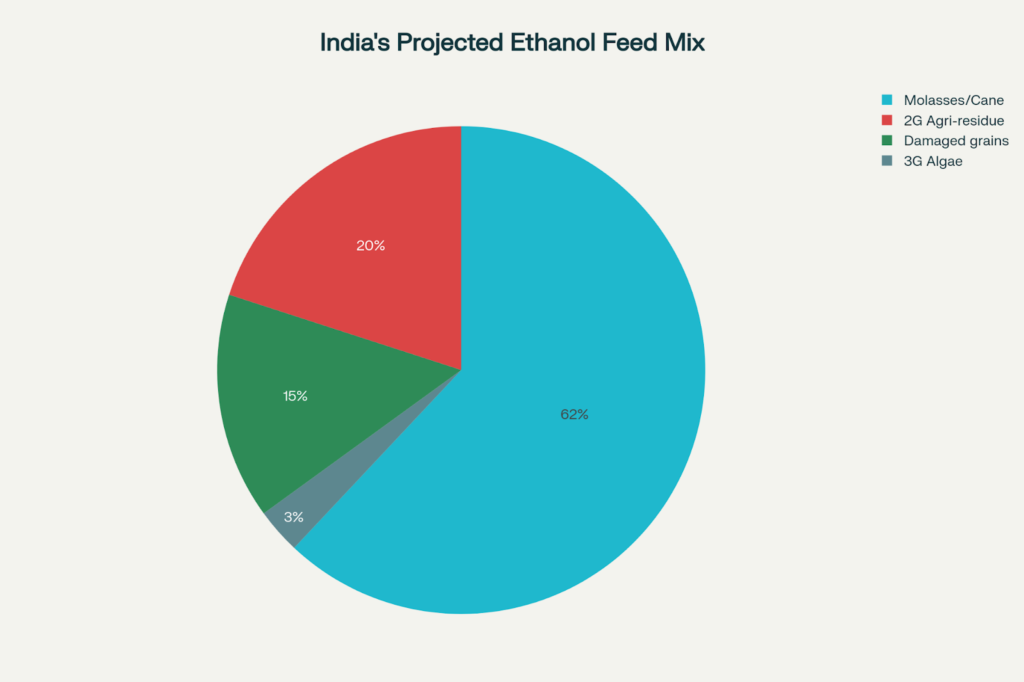

Second-generation (2G) ethanol is produced from agricultural residues such as rice straw, wheat straw, and other biomass. Instead of burning fields, it is collected and converted into clean biofuel.

This single shift solves multiple problems at once.

How 2G ethanol helps:

- Prevents stubble burning by creating demand for crop residue

- Provides additional income to farmers

- Reduces dependence on fossil fuels

- Cuts vehicle emissions through ethanol blending

- Supports India’s net-zero and climate goals

In short, what once choked our cities can now power them cleanly.

The Role of Khaitan Bio Energy

Khaitan Bio Energy is actively working to convert agricultural waste into clean, sustainable 2G Ethanol fuel. By creating a structured ecosystem for biomass collection, processing, and fuel production, the company addresses the problem at its root.

What makes Khaitan Bio Energy’s approach impactful:

- Focus on non-food biomass, avoiding food vs fuel conflict

- Support for farm-level aggregation of crop residue

- Alignment with India’s Ethanol Blending Programme (EBP)

- Contribution to rural employment and energy security

Instead of punishing farmers, this model partners with them.

Vehicle Emissions: The Other Half of the Problem

While stubble burning worsens winter pollution, vehicle emissions keep the air polluted throughout the year. Petrol and diesel vehicles release nitrogen oxides, carbon monoxide, and particulate matter.

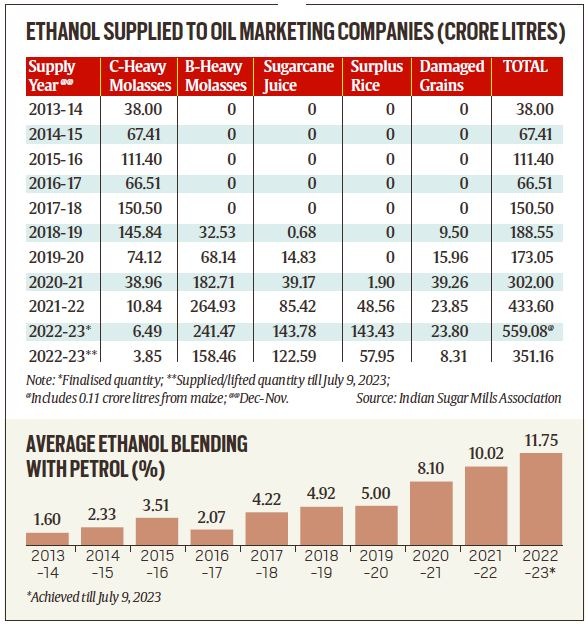

Blending ethanol with petrol reduces tailpipe emissions and improves combustion efficiency.

India’s target of 20% ethanol blending is a critical step—but achieving it sustainably requires large-scale 2G ethanol production.

One Solution, Multiple Benefits

Here’s how 2G ethanol tackles both stubble burning and vehicle pollution:

| Problem | How 2G Ethanol Helps |

| Stubble burning | Creates demand for crop residue instead of burning |

| Farmer income | Farmers earn by selling straw |

| Air pollution | Reduces smoke and particulate matter |

| Vehicle emissions | Ethanol-blended fuel burns cleaner |

| Energy imports | Lowers dependence on crude oil |

| Climate impact | Cuts greenhouse gas emissions |

Why Long-Term Thinking Matters

The Supreme Court’s criticism of CAQM reflects growing frustration with reactive governance. Emergency measures like odd-even schemes, construction bans, and school closures may provide temporary relief, but they do not address the source.

Long-term solutions require:

- Investment in biofuel infrastructure

- Farmer-centric economic incentives

- Stable policies supporting 2G ethanol

- Public-private collaboration

This is not just an environmental decision—it is an economic and social one.

A Cleaner Future Is Possible

India does not lack solutions. It lacks speed and scale in implementing them.

2G ethanol offers a rare win-win scenario:

- Farmers benefit

- Cities breathe cleaner air

- Vehicles pollute less

- The country moves closer to energy independence

Khaitan Bio Energy’s work shows that innovation backed by intent can turn one of India’s biggest environmental challenges into an opportunity for sustainable growth.

The question is no longer whether we can stop stubble burning—but how quickly we choose to act.

Final Thought

Pollution should not be the price we pay for food production or mobility. With technologies like 2G ethanol, India has the chance to rewrite this story—one harvest, one fuel, and one breath at a time.