India, the world’s third-largest energy consumer, faces an ever-increasing demand for fuel as its economy and population continue to grow. In response to this challenge, the country has been making significant strides in harnessing bioenergy progre, aiming to reduce its dependence on fossil fuels, cutting greenhouse gas emissions, and promoting sustainable development. Bioenergy, which refers to energy derived from organic materials (biomass), plays a crucial role in India’s renewable energy landscape, complementing its solar and wind energy initiatives.

India’s progress in bioenergy has been largely driven by the need to achieve multiple objectives: improving energy security, supporting rural economies, reducing air pollution, and addressing climate change commitments under the Paris Agreement. In this comprehensive blog, we’ll explore the key aspects of India’s bioenergy journey, including the Ethanol Blending Program, biogas and bio-CNG initiatives, biodiesel development, and the future potential of advanced biofuels.

Ethanol Blending Program (EBP)

One of the most prominent bioenergy initiatives in India is the Ethanol Blending Program (EBP). This program involves blending ethanol, a renewable biofuel, with petrol to reduce the country’s reliance on imported fossil fuels and lower emissions.

Bioenergy Progress: India’s Ambitious Targets

India set an ambitious target of achieving 20% ethanol blending (E20) by 2025, significantly advancing from the earlier target of 2030. The idea is to reduce the carbon footprint of its transportation sector, which is responsible for a significant share of emissions. By blending ethanol with petrol, India can achieve cleaner combustion in engines and reduce harmful pollutants.

Progress So Far

As of 2023, India achieved over 10% ethanol blending, a significant milestone considering the challenges in production, supply chain, and infrastructure. The blending rate has been increasing steadily due to the government’s push for both first-generation ethanol (produced from sugarcane and other food crops) and second-generation ethanol (produced from biomass and non-food sources). The National Biofuels Policy (2018) was instrumental in providing a policy framework for scaling ethanol production.

Focus on Second-Generation (2G) Ethanol

The government has already inaugurated 2G ethanol plants, such as the one in Panipat, Haryana, which is a key part of this transition. These plants convert agricultural waste into ethanol, providing a sustainable solution for both energy production and waste management.

During the opening session of the India Bio-Energy & Tech Expo 2024 (IBETE), Shri Hardeep Singh Puri, the Minister for Petroleum & Natural Gas of India, provided an in-depth overview of India’s advancements in the bioenergy sector and its significant contribution to the nation’s energy transition. Minister Puri highlighted that bioenergy is progressively emerging as an essential substitute for fossil fuels, presenting both ecological advantages and economic prospects, especially in rural communities.

He highlighted one of the major wins: India’s ethanol blending program. Since it kicked off, the blending rate has jumped from 1.53% in 2014 to a solid 15% in 2024. Riding on this momentum, the government is aiming high with a target of 20% blending by 2025 and is making good strides toward that goal. Over the last ten years, this initiative has brought about some impressive results, like saving Rs. 99,014 crore in foreign exchange, cutting down CO2 emissions by 519 lakh metric tons, and replacing 173 lakh metric tons of crude oil. Plus, it had a big economic boost, with Oil Marketing Companies paying out Rs. 1,45,930 crore to distillers and Rs. 87,558 crore to farmers.

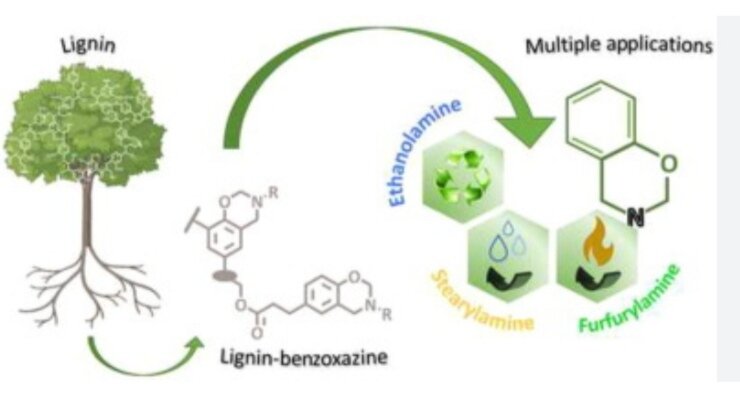

Sustainable Aviation Fuel (SAF): The Next Frontier

As India continues to develop its bioenergy sector, one of the exciting areas of innovation is the production of Sustainable Aviation Fuel (SAF). Therefore SAF is a biofuel used to power aircraft, and it is seen as a critical component of reducing the carbon footprint of the aviation industry, which is notoriously difficult to decarbonize.

Bioenergy Progress: India’s SAF Initiatives

A major highlight of India’s ethanol strategy is the focus on second-generation (2G) ethanol. Unlike first-generation ethanol, which is produced from food crops like sugarcane, 2G ethanol is produced from agricultural residue, such as rice straw, wheat straw, and other forms of biomass. This not only reduces competition with food resources but also helps in addressing the persistent problem of stubble burning in states like Punjab and Haryana, which contributes to severe air pollution.

India is exploring the production of SAF using feedstocks like non-edible oils, agricultural residue, and other forms of biomass. Thus by integrating SAF into its aviation fuel mix, India aims to reduce its dependency on imported jet fuel and contribute to global efforts to lower aviation-related emissions. SAF production is still in its early stages, but with increasing technological advancements, it holds significant potential for the future.

Bioenergy and India’s Climate Goals

India’s progress in bioenergy is closely aligned with its Nationally Determined Contributions (NDCs) under the Paris Agreement. One of India’s key NDCs is to reduce the carbon intensity of its economy by 33-35% by 2030. Bioenergy, along with solar and wind energy, is seen as a key driver in achieving this goal.

By promoting ethanol blending, India is not only reducing its carbon emissions but also creating new economic opportunities, particularly in rural areas and helping farmers gain additional income. Bioenergy also contributes to improving air quality, reducing waste, and promoting sustainable agricultural practices.

Bioenergy Progress: Challenges and the Road Ahead

While India has made considerable progress in bioenergy, several challenges remain. These include:

- Feedstock availability: Ensuring a consistent supply of biomass and organic waste for biofuel production.

- Infrastructure development: Expanding biofuel production facilities and distribution networks.

- Technological advancements: Improving the efficiency and cost-effectiveness of second-generation biofuel technologies.

- Policy support: Maintaining a stable and supportive policy environment to attract investments and encourage innovation.

The road ahead for India’s bioenergy sector is promising. With continued government support, technological advancements, and growing environmental awareness, bioenergy will play an increasingly important role in India’s transition to a sustainable energy future.

Conclusion

India’s bioenergy progress is a testament to the country’s commitment to achieving energy security, reducing emissions, and promoting sustainable development. Thus from ethanol blending and biogas production to the potential of sustainable aviation fuels, India is exploring diverse avenues to harness the power of bioenergy. As the world looks for cleaner and more sustainable energy solutions, India’s efforts in the bioenergy sector offer a promising path forward, not only for the country but for global energy transitions.