Introducing ethanol for global needs

Ethanol is a colourless liquid and a biodegradable fuel. The low toxicity has proved ethanol to cause minimal ecological pollution. It is a high-density fuel which replaces “lead” as an octane enhancer in gasoline. Three kinds of microorganisms are responsible for converting lignocellulosic biomass to bioethanol. These microbes are yeasts, bacteria, and fungi. Among them, yeasts proved to be the best for the ageing process. Combining ethylene with steam is an alternate way to produce ethanol. Mixing ethanol with gas can oxygenate the fuel blend, which burns the whole compound—thus reducing emissions of pollutants.

Depleting natural resources adversely affects the planet. So, the governments of each country are bound to take action. Most organisations are taking the initiative and bringing new technology to biofuel production. Among the biofuels, bioethanol has proved to be a promising fuel to address the energy crisis. In the transportation sector, bioethanol serves as an alternative to petroleum derivatives. Conversion of bioethanol with hydrocarbons, oxygen synthetics and other low atom-weight molecules results in a superior blend.

Classifications

Bio Ethanol is classified into two groups;

Classification of bioethanol through the process of manufacturing.

- The traditional method of producing ethanol combines ethylene with steam. It has a chemical reaction by using non-biogenic sources of raw materials. In which ethylene is non-renewable.

- Anaerobic sugar fermentation from various renewable sources is a sustainable method of producing ethanol with the help of microbes.

Classification of bioethanol by the source of raw materials.

First Generation (1G) Bioethanol

Raw materials extracted from food-based feedstocks to produce ethanol are sugar and starch, a common type of alcohol. Sugar cane, sorghum, and pearl millets contain glucose, sucrose, and fructose. These are the major components of such feedstocks. This bioethanol production process is not cost-effective, raising the criticism of adopting non-food-based feedstocks.

Second Generation (2G) Bioethanol

Second-generation bioethanol consists of lignocellulosic biomass and industrial wastes. It is readily available and also found in all sectors. Hence, the scope of second-generation ethanol is very promising. But unfortunately, the functioning of these industries depends upon the market demand for ethanol.

Third Generation (3G) Bioethanol

Bioethanol from non-food based feedstock includes many benefits. Such as higher energy density, conversion percentage, ease of cultivation, and lower costs. However, there is a lack of stability in the extraction of algae or other microbes compared to other bioethanol sources.

Fourth Generation (4G) Bioethanol

The fourth-generation bioethanol procedure includes capturing and storing CO2 and later converting the stored CO2 to ethanol. Oxide electrolysis, genetic engineering, and petroleum hydro-processing are some technologies. However, it is in the embryonic stage.

The Properties and Process of Bioethanol

Properties

Ethanol is a popular biofuel which is readily available in the market. The fuel has the potential of conversion to secondary energy resources. Using bioethanol as a transport fuel reduces greenhouse gas (GHG) emissions compared to gasoline or octane. The biodegradation of bioethanol is simple. In contrast to petrol and water, bioethanol is entirely miscible with water in all ratios. While gasoline is immiscible when blended with water. It might cause corrosion-related issues with the mechanical parts particularly those made of copper, brass, or aluminum. Ethanol increases octane more effectively and contains 35% oxygen by mass. It requires fewer additives in its process and pollutes water bodies less. Ethanol improves fuel combustion and lowers particle emissions released during combustion.

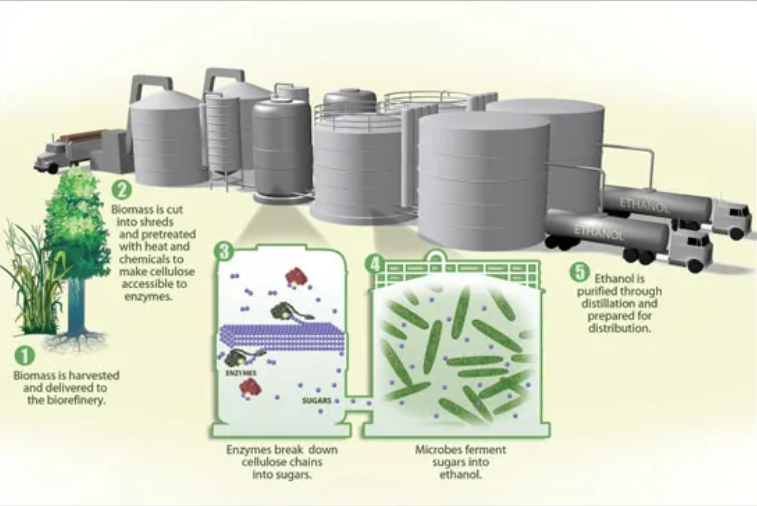

“Process of Bioethanol Production”

Process

Bioethanol manufacturing uses biomass (starch and lignocellulosic) as a raw material for a more sustainable alternative. Technologies for developing bioethanol through research, primarily focused on the conversion of biomass waste.

Bioethanol manufacturing from starch involves three sequential steps:

- Hydrolysis

- Fermentation

- product purification.

However, bioethanol from lignocellulosic biomass involves four steps:

- Pretreatment

- Hydrolysis

- Fermentation

- Purification

Pretreatment procedures

- Physically

- Physio-chemically

- Chemically

- Biologically

It is crucial to choose the best pretreatment strategy. Thus, focus on creating and applying suitable pretreatment techniques and the other phases of bioethanol production.

Possibilities of Bioethanol

Bioethanol-gasoline mixed in the proportion of 10% bioethanol and 90% gasoline is most popularly known as gasohol(E10). Most modern automobiles that run on “internal combustion engines”(ICEs) could quickly burn E10. Bioethanol only acts as a traditional motor fuel by combining with other propellants. The vehicle performance is not degraded with use of ethanol with other blends in such quantity by conventional combustion. This mixture does not need alterations while burning. Blended fuels like E85 contain 85 per cent bioethanol and 15 per cent gasoline.

In recent decades, significant advancements have developed in processing renewable biomass, including cellulose synthesis, pentose and hexose sugar fermentation, and the separation and purification of bioethanol.

Despite these advancements, only sugarcane bioethanol produced in Brazil can match the price of fossil fuels. They regularly conduct market studies, polls, and crop selections, giving them a competitive edge in ethanol’s growth and loss-free production.

The use of synthetic biology and yeast metabolic engineering has a considerable positive impact on future industrial bioethanol production systems.

The availability of biomass and the cost of ethanol are the two limiting factors in the production and use of bioethanol. There are many potential applications for ethanol across several industries.

Analysis

For several biomass feedstocks, Oak Ridge National Laboratory introduced supply cost curves. They found that 144 million dry tonnes of agricultural leftovers are accessible and collected yearly. According to the estimates, this equates to 10–14 billion gallons of bioethanol per year. As a result, without having to compete for any new land. The current biomass sources are sufficient to cover about 10% of our needs for light-duty vehicle transportation.

The growth of energy crops will expand the bioethanol market. Economic modelling supports the research of bioethanol’s market penetration. These predictions stated that if ethanol price is $1 per gallon, bioethanol sales will reach 2 billion gallons annually.

Industry can only lower the cost of ethanol to 80 cents per gallon if yearly ethanol demand reaches 6 or 8 billion gallons. This statement is a feasible target based on recent techno-economic studies.

The United States are one of the significant consumers of ethanol. If farmers are encouraged to cultivate corn more than the paddy, the amount of ethanol generated throughout the country will increase. Cooperative distilleries and production facilities provide financial assistance, and ethanol is sold across all nations at a consistent price and on a dependable market.

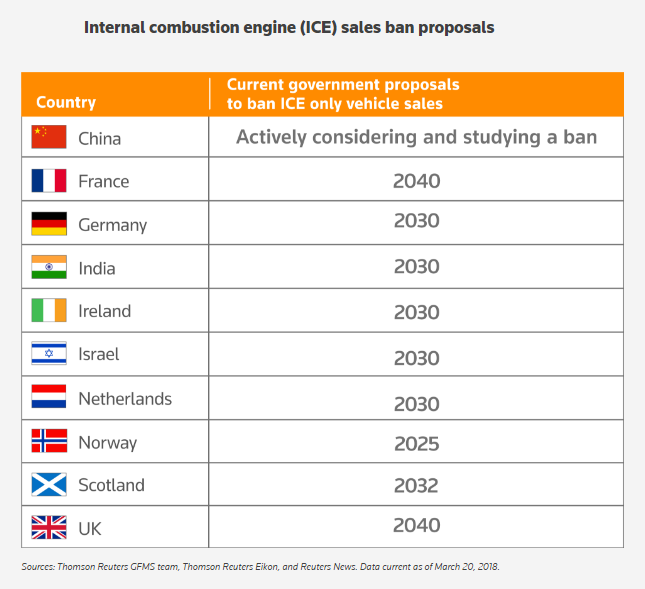

“Ban on Internal Combustion Engines by Countries”

Major country’s projects and policies

Nations are struggling to reduce their contribution to carbon emissions, reflecting a negative impact on the planet. A significant issue addressed was temperature rise, leading to melting polar caps.

So, it was about time the nations agreed upon the decarbonisation pact, prompting the “net-zero” concept.

It is to enhance air quality and creating a healthier environment for the future. This generally entails reducing greenhouse gas emissions, conserving water, maximising energy resources, and eliminating waste. Hence, this results in society’s development being more sustainable and adaptable.

Phasing out fossil fuel

Britain became the first G7 nation in the previous year to achieve the net-zero emission target by 2050. This goal calls for significant changes in how Britons travel, consume energy, and eat. Starting from 2030, Britain will ban the sale of petrol and diesel five years earlier than anticipated. Prime Minister Boris quoted this as the “Green Revolution” and focused on reducing emissions to zero by 2050.

However, not only Britain, below are the following nations or regions that have proposed prohibiting vehicles powered by fossil fuels:

USA: In September 2035, Governor Gavin Newsom announced that California would prohibit the sale of new gasoline-powered passenger automobiles and trucks.

Canada: Quebec said that starting in 2035, it would prohibit the sale of new gasoline-powered passenger vehicles.

European Union: On October 23, EU environment ministers agreed to make the bloc’s 2050 net-zero emissions target legally enforceable, but left it up to the leaders to decide on a 2030 carbon reduction target in December.

Germany: In late 2018, German localities began enacting bans on older diesel cars that create more pollution.

Norway: With a target date of 2025, Norway, whose economy is strongly dependent on oil and gas revenue, wants to be the first nation in the world to ban the sale of cars that run on fossil fuels.

In Norway, sales of fully electric vehicles already account for around 60% of all monthly sales.

China: China began researching when it would be appropriate to prohibit manufacturing and selling automobiles that use conventional fossil fuels in 2017.

According to an industry official, new energy vehicle (NEV) sales in China, the world’s largest auto market, will account for half of the recent car sales by 2035.

India: Last year, the country’s national think tank urged scooter and motorcycle manufacturers to develop an electric vehicle transition strategy.

In addition, by 2025, electric scooters with 150cc engines will be manufactured and distributed.

India’s Policies and Projects

Focusing more on second and third-generation bio-ethanol is a crucial strategy for increasing the nation’s ethanol production. Food grains and sugarcane juice for ethanol generation have always come under research in a developing country like India. Therefore, combining household and agricultural waste to produce biofuel will help the supply issue. India produces very little second-generation biofuel at the moment. However, in recent years, public sector oil marketing firms like the Indian Oil Corporation and Bharat Petroleum have established production facilities and invested in the manufacture of second-generation biofuels. The industry has yet to see the effects of these advances.

By 2030, India’s net agricultural residue availability for biofuel generation is approximately 166.6 million tons.

By the same year, the demand for ethanol for gasoline blending would be close to 13.7 million tons (based on the desired mixing rate of 20%).

The development of technology to produce ethanol from cellulosic and lignocellulosic biomass would help focus attention away from food-based biofuels and prevent a future shortage of ethanol feedstock.

Discussions

At a recent state-level conference organized at an institute in Pune, the union minister addressed the issue of switching to alternative fuel ethanol in construction, flex-fueled engines and the agriculture industry, where diesel-based agricultural equipment switches towards gasoline. Similarly, the union road transport and highways minister stated that petroleum products worth $10 trillion (US dollars) lead to imports to meet the needs of the energy and power sectors. In the coming years, the demand for imports may increase to 25 trillion (US dollars), resulting in an economic crisis.

The minister also mentioned that a rise in demand for sugar throughout the globe is a temporary phenomenon. However, there is an urgency in shifting sugar production to ethanol due to policies established.

Brazil manufactures ethanol from sugarcane as crude oil prices rise to $140 per barrel, increasing the demand for sugar from India.

Brazil begins to produce sugar when crude oil prices fall from $70 to $80 per barrel, and when crude oil prices fall, it also reflects a decrease in sugar demand.

Future government measures to encourage the manufacture of ethanol from corn will also be a crucial tactic. Compared to rice or sugarcane, corn takes much less water to grow.

Additionally, reducing the amount of water used for paddy production will aid India, which otherwise could soon experience severe water shortages.

All these actions can decrease the amount of foreign currency, mostly spent on importing fuel, while also assisting India in increasing ethanol production and blending rates.

ETHANOL BLENDING PETROL PROGRAMME (EBP)

The Ethanol Blending Program (EBP) aims to meet the ethanol blend targets combined with gasoline.

Goal: By reducing fuel imports and lowering carbon emissions, it wants to combine ethanol with gasoline, classifying it as a biofuel and saving millions of dollars.

Target: Since ethanol is a cleaner fuel, it is added to a different propellent to lessen the nation’s reliance on petroleum imports. The objective is to reach a 20 per cent ethanol blend in Fuel by 2025, referred to as “E20” in the industry.

In 2018, the Central Government expanded the scope of the EBP programme to extract Fuel from surplus amounts of food grains like remains of fruits and vegetables, sorghum, and pearl millet. Only extra sugarcane production could turn into ethanol for programme purchases.

The government will offer interest subsidies (on loans) to encourage funding in this industry. Blending 20 per cent of ethanol into gasoline by the year 2050 is set up under the Ethanol Blended Petrol (EBP) Program.

Additional Ethanol Demand Scenarios Modeling:

One of India’s top think tanks, the Center for Study of Science, Technology and Policy (CSTEP), utilized “Sustainable Alternative Futures for India”(SAFARI), a long-term simulation model to forecast the demand for ethanol. According to the SAFARI model, socioeconomic elements, including population, GDP, and development objectives, would impact India’s energy consumption and emissions by 2050. Development goals refer to access to food, housing, healthcare, education, transportation, power, and infrastructure.

As the electric vehicle revolution is on the horizon, many uncertainties in future projects are to focus on research and development in different scenarios. Three scenarios for electric mobility uptake to estimate the demand for petrol and ethanol are:

1. Conservative (low EVs) – negligible uptake of electric mobility up to 2030.

2. The Status Quo (BAU, medium EVs): medium uptake of electric mobility, around 15% of car passenger kilometres (pkm) and 30% of two-wheeler and three-wheeler pkm are assumed to be electric by 2030.

3. Low Carbon (high EV uptake): 30% of cars and 80%of two-wheelers and three-wheelers are assumed to be electric by 2030.

Additional Initiatives

E20 Fuel

The Indian government established a 20 per cent ethanol blend in gasoline known as E20 Fuel as its target by 2025. The Indian government has encouraged public comments presenting the acceptance of E20 Fuel.

JI-VAN Pradhan Mantri (2019).

The plan aims to create a biological system for launching business strategies and promote creative projects and initiatives in the 2G ethanol sector.

The Public Biofuel Policy (2018)

MNRE approves this policy to achieve the target of 20% ethanol blended with petrol and 5% biodiesel blended with diesel by 2030.

Reduction in GST

The government has reduced GST on ethanol from 18 per cent to 5 per cent, initiated under the Ethanol Blended Petrol Program (EBP).

Conclusion

The pretreatment of renewable biomass, the production of cellulase, the fermentation of sugars (pentose and hexose), and the separation and purification of bioethanol have seen significant developments in recent decades. Despite these advancements, only Brazil’s bioethanol from sugar cane production makes bioethanol cost-competitive with fossil fuels. They carry out market research and surveys each year and select crops each year, which provides them with a cutting edge to cultivate and produce ethanol without much loss.

Yeasts, especially S. cerevisiae, have long been the masters of alcoholic fermentation. They play a pivotal role in one of the world’s most critical biotechnological sectors. The scope of yeast metabolic engineering and synthetic biology will significantly benefit future industrial bioethanol production system projects. Saccharomyces cerevisiae yeast is an important microorganism used in many sectors. It helps to make various commercial products such as baked goods, alcoholic beverages, biofuels, and medications.

Bioethanol has the potential to significantly reduce the adverse effects of greenhouse gas emissions from fossil fuels, thereby limiting global warming.

Particularly with the policies, there is still considerable space for improvement. However, analysing the future market demand, ethanol manufacturing seems to have a promising future.