Biodiesel is a diesel substitute fuel in diesel engines. Biodiesel is a renewable liquid fuel that is a non-toxic, biodegradable fuel—produced from alcohol, vegetable oil, animal fat, or recycled cooking grease. It burns cleaner than its petroleum derivatives. The extraction of biodiesel uses plant oils (e.g., soybean oil, cottonseed oil, canola oil, corn oil), recycled cooking greases (e.g., yellow grease), or animal fats (beef tallow, pork lard). Cooking oils are typically extracted from plants, but animal fats are occasionally included. Recycling and regenerating used cooking oils is regarded as a long-term solution.

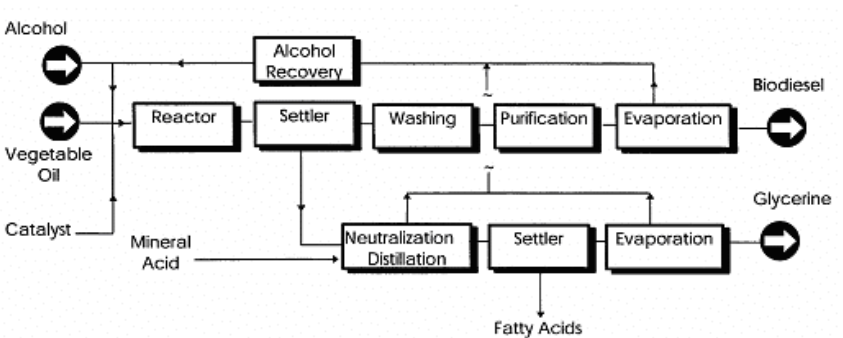

The development of new feedstocks for biodiesel is in its early stages. Some examples of such crops are pennycress, camelina, brown grease, and algae strains. However, there is currently a lesser percentage of biodiesel available from these feedstocks. But these feedstocks have great potential to supplement the feedstock supply. Oils and Fats are converted into chemicals known as long-chain fatty acids or mono alkyl esters, which is the organic compound name of biodiesel. During the manufacturing process, These chemicals are known to be FAME – Which means “Fatty Acid Methyl Esters”, and the process is known to be esterification.

Production of 100 pounds of biodiesel and 10 pounds of glycerin needs 100 pounds of oil fats, 10 pounds of short-chain alcohol and the presence of a catalyst. Usually, methanol is used as an alcohol base. The catalyst is an activator that ensures the chemical reactions of the base components. The usual catalyst used in the process is sodium hydroxide and potassium hydroxide or glycerol. The sugar produced byproduct of the biodiesel process is known as glycerin.

Biodiesel meets the criteria of Renewable Fuel Standard’s biomass-based diesel and advanced biofuel requirements. There is a difference between renewable diesel, also known as “green diesel,” and biodiesel. Usually, biodiesel is known as B100 or neat diesel in its pure, unblended form. Petroleum derived biodiesel is used to power compression-ignition (diesel) engines. It can be blended with petroleum diesel in any percentage, including B100 (pure form) and the most popular blend, B20 (a blend of 20% biodiesel and 80% petroleum diesel).

Blends with lower percentages perform better in cold temperatures. Regular No. 2 diesel and B5 usually perform similarly in cold weather. Some biodiesel blends and No. 2 diesel compounds crystallise at extremely low temperatures. Fuel blenders and suppliers use a cold flow improver to combat crystallisation in cold weather. Fuel providers usually inform the user regarding the proper cold weather blend.

The United States Environmental Agency has legally registered the fuel and fuel additive (EPA). The EPA registration covers all biodiesel that meets the ASTM standard specification regardless of the feedstock or process of the fuel.

Benefits of Biodiesel

Health Effects

PM and hydrocarbon emissions from diesel engines may be hazardous to human health. The Mining Safety and Health Administration discovered that switching from diesel fuel to high biodiesel blend levels (B50 to B100) significantly reduced PM emissions. However, even low concentrations of biodiesel reduce PM emissions and provide significant health and compliance benefits wherever humans are exposed to diesel exhaust.

Easy to Use

One of the most significant advantages of using biodiesel is its ease of use and efficiency. Different blends provide different qualities. However, each combination has its characteristics, handling requirements, and preventive measures. B20 or lower blends, for example, require no new equipment or modifications, and B20 can be stored in diesel fuel tanks and pumped using the same equipment as diesel fuel.

Safety

A spill of pure, unblended biodiesel causes much less environmental damage than a spill of petroleum diesel. There is a lower risk of combustion than with petroleum diesel. Petroleum diesel has a flashpoint of around 52°C, whereas biodiesel has a flashpoint of over 130°C. However, without prior knowledge or experience, the manufacturing procedure can be dangerous. Necessary precautions are mandatory for production purposes.

Air Quality

Manufacturing vehicle engine demands to meet all the specific emission standards before moving on to further process. Whether it runs on petrol, diesel or any other alternative fuel doesn’t matter. Selective catalytic reduction technology in diesel vehicles has now achieved a net-zero nitrogen oxide emission. It also lowers the total carbon life cycle emissions in the long run. A study on “carbon emissions of fuels” found that the B100 blend of biodiesel reduces carbon dioxide emission by 74% compared to petroleum diesel.

Reduces Greenhouse Gas Emissions

When oilseed plants grow, they absorb carbon dioxide (CO2) from the atmosphere and use it to create stems, roots, leaves, and seeds. After the oil from the oilseeds is extracted, it is converted into biodiesel. CO2 and other emissions are released and returned to the atmosphere when burned. Most of the CO2 emitted does not contribute to the net CO2 concentration in the atmosphere because the next oilseed crop will reuse the CO2 as it grows. Because of the use of fossil fuels and chemicals in farming and biodiesel production, a small portion of the carbon emitted is fossil-derived.

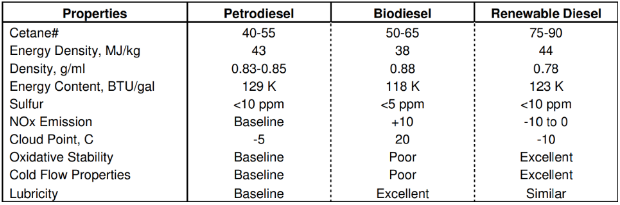

Enhances Engine Performance

Low concentrations of biodiesel improve fuel lubricity and increase the fuel’s cetane number. Diesel engines rely on engine lubrication. Moving parts in vehicles, particularly fuel pumps and injectors, wear out prematurely if the lubricant is insufficient. Diesel fuel has blend levels as low as 1%, indicating its poor natural lubricity. However, biodiesel adds lubricity to diesel, improving its quality.

Reduces Tailpipe Emissions

Biodiesel is fully compatible with the emission control catalysts and filters that drastically reduce Nitrogen oxides and PM emissions from new diesel engines (NDEs). Older technology diesel engines emit NOx way more than the sufficient limit which has been a concern. But replacing older engines with newer ones has mitigated some of these emissions concerns.

Biodiesel vs Fossil fuel

Compared with fossil fuels, biodiesel has some limitations which cause few setbacks. Such as

- Very high cost of production compared to petrodiesel.

- Lower calorific power compared to its alternative fuels.

- It can become rancid due to oxidation and bacterial air, affecting long-term storage stability.

- It usually demands more additives due to high cloud points, especially in cold countries.

- Due release of aldehydes, ketones, and acids can result in unpleasant odours.

- Higher percentage of biodiesel sometimes causes degradation in certain types of natural rubbers.

- Biodiesel contributes to agricultural and rural development.

- Biodiesel contributes to the diversification of energy sources, which is vital for countries without access to fossil fuels.

Comparison chart of biodiesel with petrodiesel and renewable diesel

Primary Sources of Biodiesel Production

- United States – Soybeans are the most common biodiesel source.

- Europe – Field crops like Rapeseed and Sunflower are commonly preferred.

- Malaysia and The Philippines – Palm is considered a significant source of fuel production.

- Nicaragua – Jatropha curcus is the essential source for production.

- India – Focusing on Jatropha seeds. It is a tree-borne oil seed found in forest areas or wastelands. Jatropha seeds are currently under study due to their poor quality, limited regions of wastelands, and high maintenance cost for better yield. Further research is in place for better alternative oil seeds to Jatropha seeds.

Grease and animal fats are also essential resources that are more plentiful than the yielding crops. These feedstocks may also be less harmful to the environment than crops.