In the quest for cleaner energy sources, bioethanol has emerged as a significant player. Ethanol is produced by fermenting organic materials and used as a renewable fuel to replace or complement gasoline. However, not all ethanol is the same. Two main types exist: first-generation ethanol (1G) and second-generation ethanol (2G), and they differ in both production methods and environmental impact.

As we strive to reduce greenhouse gas (GHG) emissions and minimize our dependence on fossil fuels, 2G ethanol is proving to be a more sustainable option. This blog will explore how 2G ethanol stands out, its benefits for the environment, and why it is an ideal choice for the future of renewable fuels.

What Is 1G Ethanol?

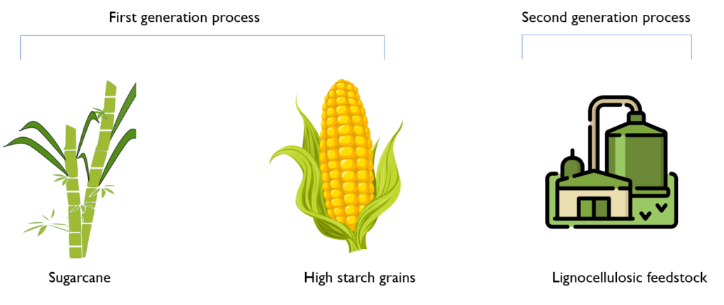

It is also known as first-generation ethanol, is produced from sugar- or starch-based crops. The most common crops used for 1G ethanol include corn in the U.S. and sugarcane in Brazil. These crops are rich in easily fermentable sugars, which makes the production process relatively simple.

However, this approach has a major downside: it competes with food production. Corn and sugarcane are essential for feeding large populations, and diverting these crops to fuel production can create food shortages and drive up prices.

What Is 2G Ethanol?

2G ethanol, or second-generation ethanol, uses lignocellulosic biomass — the inedible parts of plants like straw, wood chips, and agricultural residues. It doesn’t rely on food crops but instead utilizes waste materials and non-food plants. By making use of these discarded or low-value materials which would otherwise would’ve been burned in open fields, 2G ethanol offers a much more sustainable solution.

Unlike 1G ethanol, 2G ethanol does not compete with the food chain, addressing one of the primary concerns associated with biofuels. The main feedstocks for 2G ethanol include plant waste, grasses like switchgrass and miscanthus, and other non-edible biomass sources.

The Environmental Benefits of 2G Ethanol

One of the most significant advantages of 2G ethanol is its greater reduction of greenhouse gas emissions. The production of 1G ethanol already offers some benefits compared to traditional fossil fuels, but its GHG emissions are still substantial due to the energy required to grow, harvest, and process food crops.

In contrast, 2G ethanol has the potential to reduce GHG emissions by 88% to 108% compared to gasoline. This impressive reduction is achieved because 2G ethanol uses agricultural waste and non-food plants, which require less intensive farming practices. Moreover, these plants absorb CO₂ while growing, offsetting much of the CO₂ released during its production and combustion.

1G Ethanol’s Limitation: Food vs. Fuel Debate

One of the main criticisms of 1G ethanol is that it diverts essential food crops for fuel. As the global population grows, so does the demand for food. In this context, the large-scale use of food crops like corn or sugarcane to produce biofuel can exacerbate food insecurity.

By using non-food biomass, 2G ethanol bypasses the food vs. fuel debate entirely. The use of agricultural residues, municipal plant waste, and purpose-grown grasses for bioethanol production allows us to continue growing food without interference, while still producing a renewable fuel. This makes 2G ethanol not only more ethical but also more sustainable in the long term.

The Key to Commercial Success: Lignocellulosic Feedstocks

The primary feedstock for 2G ethanol is lignocellulose, a complex mix of cellulose, hemicellulose, and lignin found in plant cell walls. These materials are not used for food, making them ideal for its production. While the process to convert lignocellulose into biofuel is more complex and requires advanced technologies, it offers an abundant and renewable source of biomass.

Lignocellulosic feedstocks are available in large quantities as agricultural and forestry residues, or from energy crops grown on marginal land unsuitable for food production. This versatility ensures that 2G ethanol production can be scaled up without compromising food security.

Why 2G Ethanol Is More Sustainable

One of the biggest advantages of 2G ethanol is its sustainability. By utilizing waste products from agriculture, forestry, and even municipal waste, it makes better use of the materials we already produce. Instead of allowing these waste products to decay and release CO₂ into the atmosphere or burning them, they can be converted into fuel, creating a closed-loop cycle that further reduces emissions.

Moreover, the plants used in 2G ethanol production often require less water, fertilizer, and pesticides compared to traditional crops like corn or sugarcane. This means that producing 2G ethanol has a much smaller environmental footprint, helping to conserve resources and reduce pollution.

Energy Efficiency and Commercialization Potential

In countries like Brazil and USA, which are the two leaders in bioethanol, commercial-scale 2G ethanol plants are already getting set up. And commercialised, however, not without its own challenges. 2G ethanol is a very new and complex technology that is yet to be established. A lot of 2G ethanol plants have shut down due to operational issues. This also includes high investment costs, high production costs and lack of infrastructure. However, technological advancements, manufacturing 2G ethanol can become more viable and ultimately cheaper than even 1G ethanol.

The process of manufacturing 2G ethanol involves breaking down the tough cellulose fibers in plant walls. This requires several stages of treatment, including pretreatment, hydrolysis, and fermentation. These steps require more energy and specialized enzymes compared to the simpler process of converting sugars from corn or sugarcane.

The key to commercialization lies in optimizing the process and integrating it with existing 1G ethanol production facilities. By using the byproducts from 1G ethanol production (such as bagasse from sugarcane), 2G ethanol can piggyback on existing infrastructure, reducing costs and improving efficiency.

Conclusion: The Future of Ethanol Is 2G

As the world moves toward cleaner energy solutions, 2G ethanol is proving to be a more sustainable and environmentally friendly alternative to traditional 1G ethanol. It has the ability to reduce GHG emissions by up to 108%. Its reliance on waste products, and its avoidance of the food chain. Thus 2G ethanol has a significant advantage in the battle against climate change.

While challenges remain in scaling up production and making the process more efficient, the future of biofuels is clear. Second-generation ethanol will play a crucial role in shaping a cleaner, greener energy sector. Governments and industries are already recognizing this. And with continued innovation, 2G ethanol could soon become a major player in the global energy market.