Our

Technology

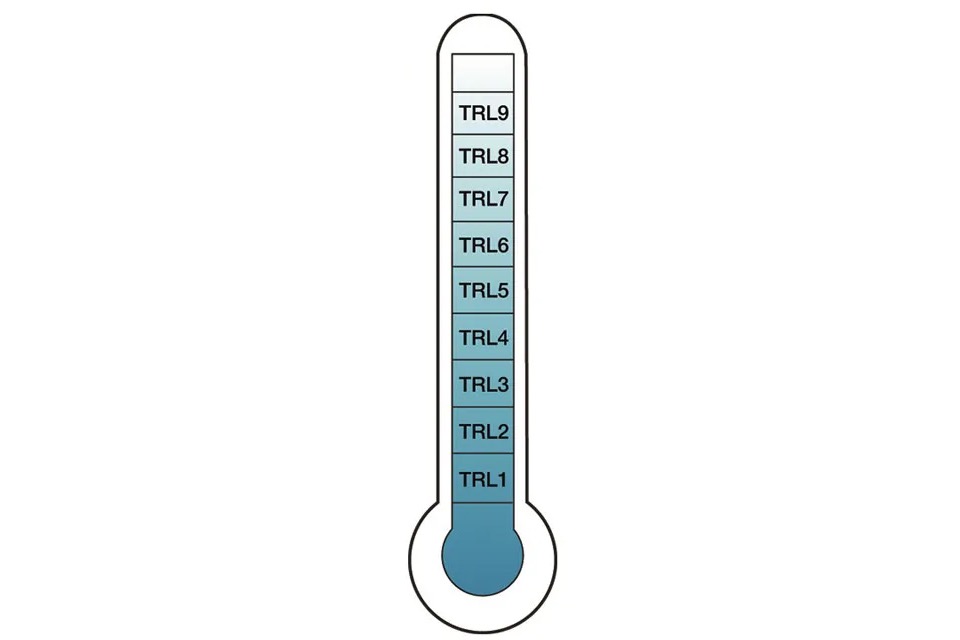

The prototype pre-commercial pilot plant has been setup under license in the premises of Kuantum Papers Limited at village Sailakhurd, district - Hoshiarpur, Punjab, India. The pilot plant is developed and engineered from scratch with the latest technology, equipment, and process. The plant uses high-efficient equipment and methods. The technology uses DCS (Distributed Control System) and Computerised automation Each process step has been optimised for production efficiency with high reliability and repeatability. The technology has been so designed so as to estabish an end to end process for a self sustained integrated biorefinery, and most importantly as a "Zero discharge facility". This technology has been certified at Technology Readiness Level - 8 (TRL-8) by the Department of Biotechnology, Government of India, thereby certifying the technology is ready for commercial deployment. The technology has also been evaluated by the Centre for High Technology, Ministry of Petroleum and Natural Gas, Government of India. It has been selected for setting up commercial Bio-refineries under the PM JIVAN Yojana, a flagship scheme to setup 2G ethanol plants based on a path breaking patented technology.

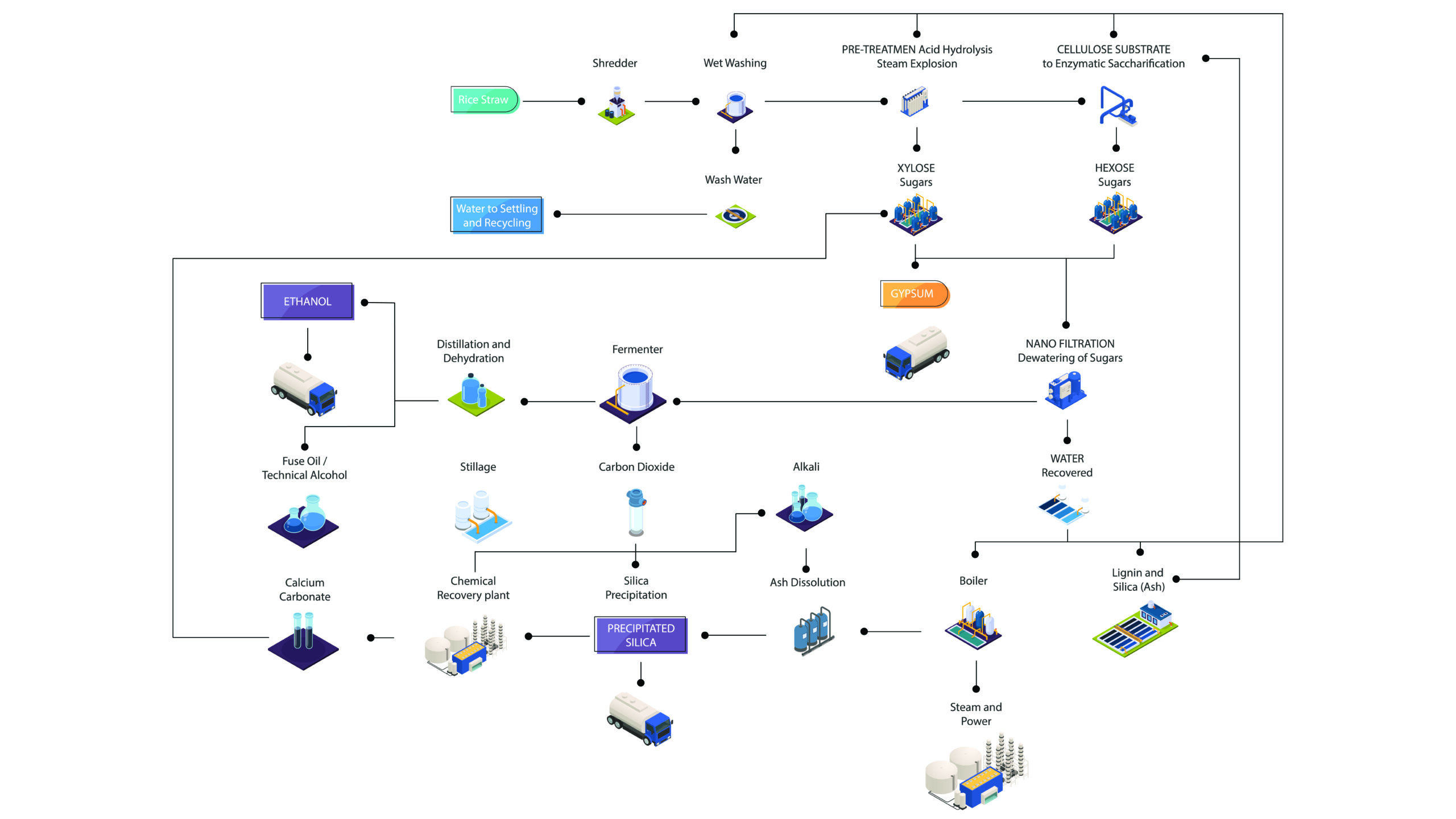

PROCESS FLOW DIAGRAM: 2G ETHANOL FROM RICE STRAW - KHAITAN BIOENERGY

The Pilot plant demonstrated end-to-end processes with the entire bio-refinery with zero discharge facility. Various new technologies are used for treating sugars, dewatering, and recycling using energy-efficient techniques, and these technologies are first in use cases in ethanol production. The process is monitored and managed with high-reliable devices and software. As is evident, we extract Silica as a high value byproduct and valorize lignin to generate steam. This is a major breakthrough in establishing commercial viability for the technology and compete with ethanol produced from other sources.

Recognitions

Certificate of Recognition by Startup India

Validation by

CHT

Granted

Patented Technology Rights

Technology Validated by BIRAC